Daikin WMC Specifications Page 5

- Page / 64

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

Catalog 602-2 5

1

1

.

.

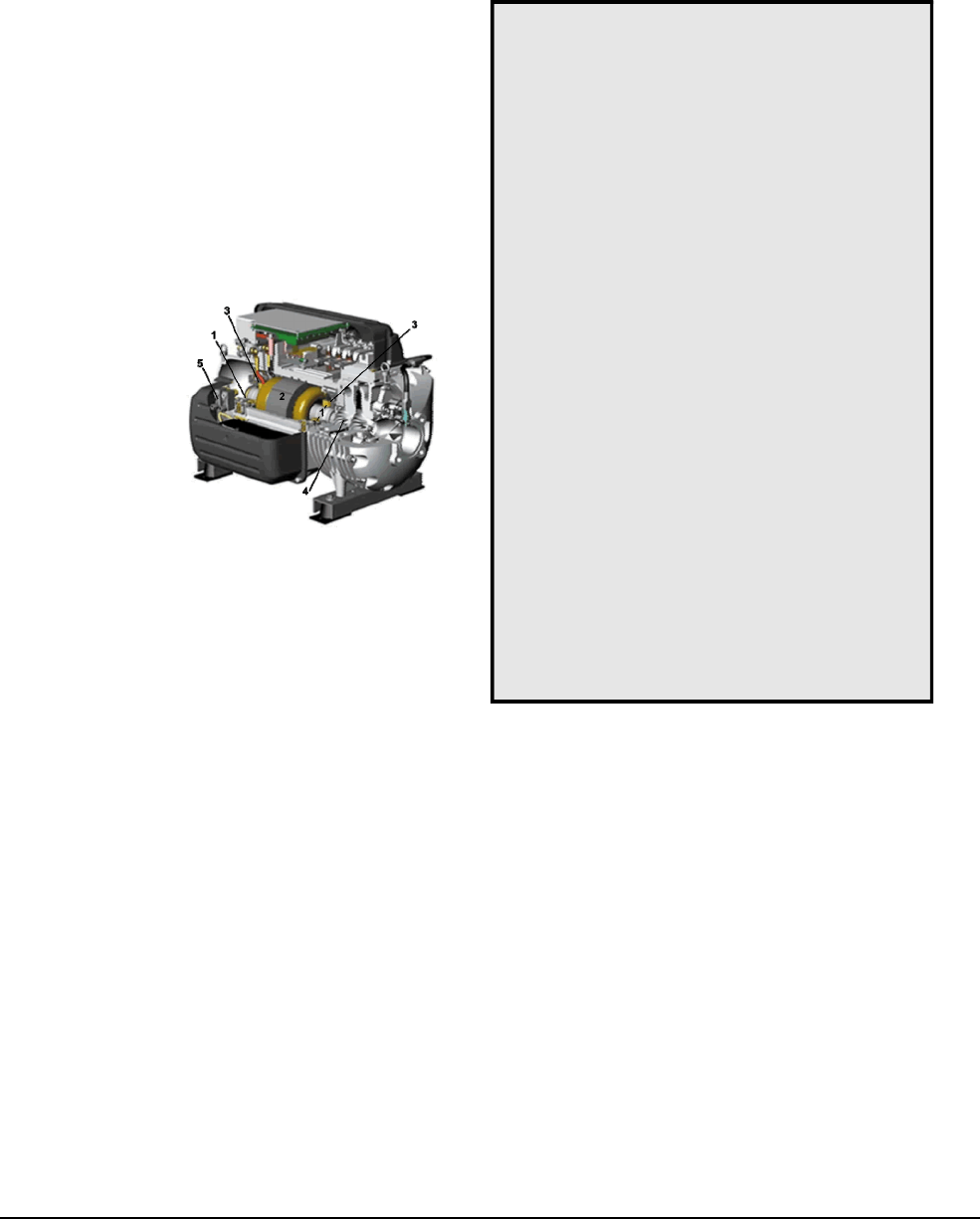

Magnetic Bearings and

Bearing Sensors

2

2

.

.

Permanent Magnet

Synchronous Motor

3

3

.

.

Touchdown Bearings

4

4

.

.

Shaft and Impellers

5

5

.

.

Compressor Cooling

6

6

.

.

VFD

Smart controls Onboard digital electronics

provide smart controls. The compressor is

totally self-correcting and incorporates a

system of sophisticated self-diagnostics,

monitoring and controls.

Safe power interruption In the event of a

power failure, the compressor motor acts as a

generator, providing power for the bearing

control system during coast down. It also has a

system to gently de-levitate the shaft.

The Compressor Technology

The advanced, magnetic bearing, permanent

magnet synchronous motor technology used in

Magnitude chillers offers many owner benefits.

Figure 1, Compressor Cutaway

VFD = Ultra-Low IPLV

The well-proven energy performance advantages

of large central plant type variable-speed

centrifugal chiller compressors now benefit

mainstream, middle-market applications through

the use of high-speed, centrifugal compression

with integral variable-speed drive.

The compressor speed reduces as the condensing

temperature and/or cooling load reduces,

optimizing energy performance through the entire

operating range. Movable inlet guide vanes

redirect gas flow into the first stage impeller

during low loads, after the compressor has reached

minimum speed.

Ultra-Smart Controls

The chillers utilize digital control electronics to

proactively

manage unit operation and providing

control of external chilled water and cooling tower

pumps.

Greater Reliability

Oil Handling Equipment Removed

With magnetic bearings operating in a magnetic

electrical field instead of oil lubricated ball or roller

friction type bearings as the basis of design, the oil

handling equipment is removed.

Oil-Free Design Benefits

Totally Oil-Free Operation = Greater Efficiency

With no oil to c oat the heat tr ansfe r sur fac es, a ga in in

he at excha nger eff iciency can be r ealiz ed.

No Oil Loss = Sustainable Performance

With no possibility of oil loss at light loads or due to worn

seals, the original energy saving efficiency can be

maintained for the life of the chiller.

No Oil Handling Equipment = Greater Reliability

With magnetic bearings operating in a magnetic electrical

field instead of oil-lubricated bearings, the oil handling

equipment is removed. No need for:

oil pumps

oil reservoirs

oil coolers

oil filters

water regulating valves

oil relief valves

oil system controls, starter, piping, heaters, etc...

that are neede d to ma inta in oil quality. The se de vices can

be a fault source in traditional chillers, and removing

them significantly increases unit and system reliability.

No Oil System = Reduced Maintenance Costs

With oil removed from the system, oil samples, oil

changes, oil system maintenance, oil filter changes and

leaks are eliminated.

- Model WMC 1

- Table of Contents 3

- The New Compressor Technology 4

- Greater Reliability 5

- Exceptional Control 6

- Unit Control Features 7

- MicroTech II 8

- Changing Setpoints 9

- Trend Logging 9

- Operating Economy 9

- Give You Even More Control 10

- Building Automation Systems 10

- Network Protocol Options 11

- Unit Design Features 12

- Catalog 602-2 13 13

- AHRI Certification 14

- Weighting 15

- Tolerances 15

- Chiller Identification 16

- Sound Data 17

- 18 Catalog 602-2 18

- Dimensions 19

- WMC 145DBS 20

- WMC 150DBS 21

- WMC250DBS 22

- WMC 290DBS 23

- WMC400DBS 24

- Catalog 602-2 25 25

- Drawing Notes 26

- Physical Data and Weights 27

- Physical Data 28

- Relief Valves 29

- Electrical Data 30

- Continued next page 31

- WMC 400D 3/60/460 ONLY 36

- Catalog 602-2 37 37

- 38 Catalog 602-2 38

- Power Factor Correction 39

- VFD Line Harmonics 39

- The IEEE 519-1991 Standard 40

- Application 41

- Considerations 41

- Condenser Water 42

- Temperature 42

- Variable Speed Chilled 42

- Water Pumping 42

- System Water Volume 43

- Pump Control 43

- Retrofit Knockdown 44

- Pressure Drop Curves 45

- Figure 20, 2-Pass Condensers 46

- (3 pass) 47

- Options and Accessories 48

- Electrical 49

- Refrigerant Recovery Units 50

- Refrigerant Monitors 51

- SPECIFICATIONS 52

- OPTIONS and ACCESSORIES 52

- Specifications 53

- 54 Catalog 602-2 54

- Catalog 602-2 55 55

- Octave Band 56

- Catalog 602-2 57 57

- 58 Catalog 602-2 58

- Catalog 602-2 59 59

- • Modbus 60

- • BACnet IP, (Annex J) 60

- Catalog 602-2 61 61

- Catalog 602-2 (2/12) 64

(24 pages)

(24 pages) (36 pages)

(36 pages)

Comments to this Manuals